TIP & TAIL ROCKER:

Character: Bends up only in the shovel and tail zones, with a camber shape in the middle

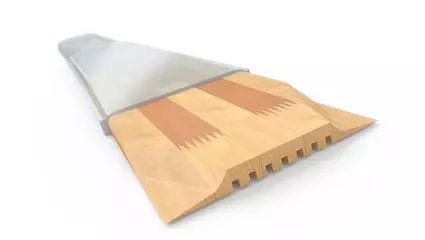

TAILORED CARBON TIPS:

In this innovative manufacturing process the new Tailored Carbon Tips are produced by embroidering the individual carbon fibers onto a carrier material. This allows them to be positioned exactly along the stress lines, opening up completely new possibilities, for performance at the front of the ski, which has a decisive influence on the handling of the ski. The stiffness, torsion and thus the skiing characteristics can be specifically adjusted via the fiber thickness and millimeter-precise alignment. In this way, the fibers guide the dynamics to the areas of the ski where they are needed. The visibly integrated Tailored Carbon Tips are light, allow an agile shovel reaction with less effort and quickly build up energy. The Tailored Carbon Tips thus reach a new level of precision, direct tip response and active skiing pleasure.

TAILORED TITANAL FRAME:

Our new key technology is called Tailored Titanal Frame. In contrast to the previous design, the width of the titanal frame is now adapted exactly to each individual ski length. This results in Tailored Titanal Frames, which are positioned above the sidewall along the tip and tail area of the ski to provide the desired damping and torsional stiffness. The size of the frames is tailored to the skier's height, skiing ability and power. This means that longer ski models have a higher titanal content for more stiffness, more direct power transmission and stronger dampening. The shorter the length, the lower the titanal content, which makes the ski more agile, so that smaller, lighter and less powerful skiers can use the full potential performance of the ski. In addition to the Tailored Titanal Frames, a second, thinner titanal layer is located in the binding area, which gives the ski the necessary strength, but also agility. The result: the Tailored Titanal Frame technology provides an incomparable combination of agility and high speed control.

FULL SIDEWALL:

Direct and strong powertransmission with full length sidewalls.

BASE P-TEX 2100:

A sintered high-density and high molecular polyethylene base with great gliding characteristics and high durability

MULTILAYER WOODCORE 1:

The side wall is laminated to extremely stable layers of wood on the sides of the sandwich core. In combination with a more flexible, lighter wood built into the center of the sandwich core construction provides numerous advantages: The hardwood part immediately adjacent to the sidewall effects a higher power transmission, improves the edge grip and supports the edge against external forces. The low weight of the softwood part in the middle of the ski brings more agility and maneuverability and reduces overall ski weight. The combination of both wood types running through the entire ski length contributes to an optimal distribution of the ski stiffness increasing the steering precision. It is the first and only sidewall/core technology intended for aggressive on-piste and racing use and capable of delivering the victory and defeat, even if it is measured in hundredths of seconds.

4 RADIUS DRIVE:

Radius 1:

Approx. 20 m in the frontmost 10 centimeters

A tighter radius only in the shovel to achieve a more immediate response to the skier‘s initial edge movement; maximum precision and agility

Radius 2:

Approx. 40 m in the area between the shovel and the binding

The open radius in the front part of the ski gives the ski more resistance to disturbances and stability at speed

Radius 3:

Approx. 15 m in the area under the binding

The tight radius in the camber area provides the ski with more agility even with slight edge movements of the skier, ensuring the necessary buildup of dynamics for short turns and radical carving curves.

Radius 4:

Approx. 25 meters in the area behind the binding up to the ski end

The moderate radius at the ski end ensures controlled and situation-adapted dynamics at the end of the turn and provides optimal support for transitioning into the next curve.